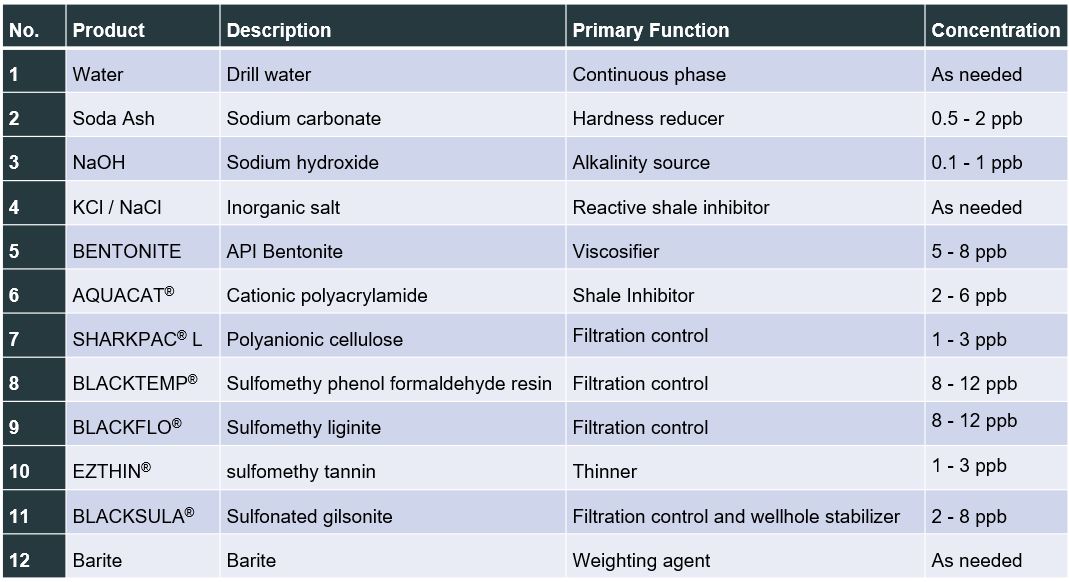

BLACK SHARK® is a classic, chrome-free, dispersed, environmentally acceptable water-based system designed to drill high-pressure/high-temperature (HP/HT) wells. Thermal stability is achieved through the combination of four main sulfonated additives in black powder including BLACKTEMP® (sulfomethy pheuol formaldehyde resin - SMP), BLACKFLO® (sulfomethy lignite - SMC), EZTHIN® (sulfomethy tannin - SMT) and BLACKSULA® (sulfonated gilsonite) to provide stable rheology and fluid-loss control. Supplement with polymeric material AQUACAT® shale inhibitor (powdered cationic polyacrylamide) to enhance borehole stability.

SHARK's expert can customize the fluid with stable properties at temperature extremes for your most demanding downhole conditions. Deploy the BLACK SHARK® water-based drilling fluid at temperatures greater than 450°F (232°C) and in the presence of contaminants with densities exceeding 19ppg (2.3 sg). Additionally, the system is stable in the presence of contamination from soluble calcium, salts and acid gases.

A summary of BLACK SHARK® water-based system's offerings:

- Long term stability of system by minimized gelation at max temperature & pressure

- Flexibility in high density and brine-based system selection

- Stability and tolerance to contaminants, resistant to reservoir components - H2S, CO2

- Optimized/controllable mud rheology

- Low HPHT filtrate with thin filter cake

- Prevention of barite settlement

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ Temperature stability can be increased with the addition of oxygen scavengers

¬ Add defoamer as required. This may be essential in salt systems

¬ Add liquid lubricant as required

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures

To ensure that the fluid formulation truly meets your required specifications, SHARK's expert will work with you to pilot test the fluid before fully deploying it as part of your drilling program.

To achieve a customized drilling fluids solution and optimized thermal stability, a suite of all items in water-based mud testing have to be conducted. Besides, special designed laboratory tests are also critical to the successful application of BLACK SHARK® system in the field.

A properly equipped mud lab on the rig with a roller oven, aging cells, and rheometer cups will be essential. Pilot testing should be carried out to determine fluid stability and proper treatments, in anticipation of all upcoming operations such as trips, cement jobs, logging etc. when the fluid will be under worst case conditions. Samples of the drilling fluid should be routinely sent into the local labs for FANN 70 and FANN 90 testing as well as routine testing on the dynamic high angle sag tester - DHAST.