Designed to deliver high penetration rates and superior wellbore stability for China Shale Gas wells drilling in an eco-friendly way, SHALEDRIL® oil-based drilling fluid system offers reliable drilling performance in environments up to 350°F.

SHALEDRIL® oil-based drilling fluids use diesel or mineral oil as the external phase for a variety of drilling applications. It is proved as one of the most economical OBM system applied in hundreds of wells in Changning, Weiyuan, Fuling Blocks.

SHALEDRIL® oil-based drilling fluids are invert emulsion systems formulated for efficiency and effectiveness. The fluids exhibit excellent lubricity for reduced torque and drag, even in high-solids drilling environments. They can also be reclaimed for use in future drilling jobs, lowering your drilling costs from one well to the next.

To ensure that the fluid formulation truly meets your required specifications, SHARK's expert will work with you to pilot test the fluid before fully deploying it as part of your drilling program.

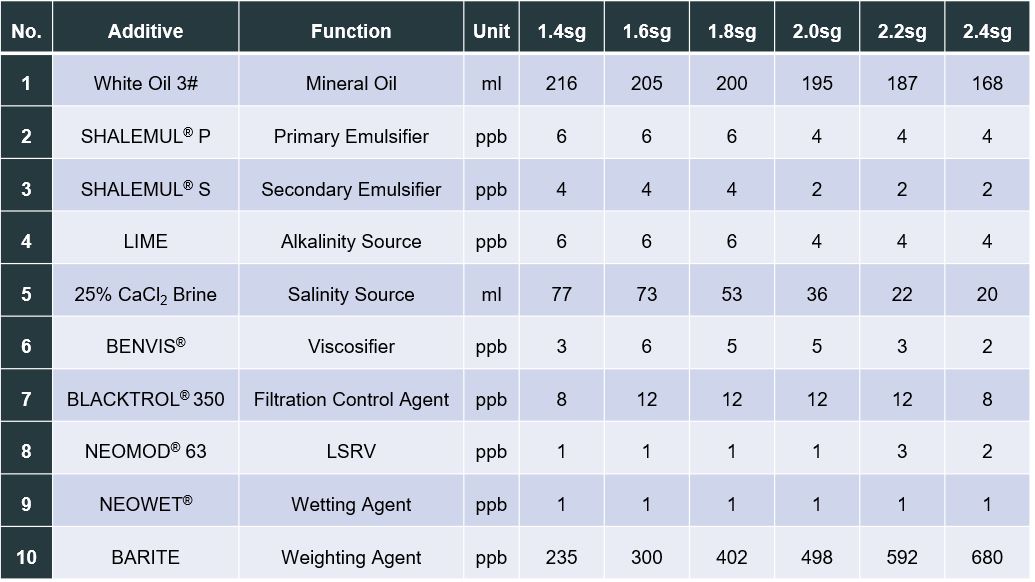

¬ The amount of each above product added into the formulation is g or ml to mix 350 ml (1bbl) volume sample.

¬ Either diesel oil or mineral oil is used as the base fluid for conventional oil-based mud systems.

¬ Use NEOMOD® 63 to enhance low shear-rate viscosities of the SHALEDRIL® system.

¬ BLACKLIGO® 350 can be used as alternative of BLACKTROL® 350 if asphalt and gilsonite are not allowed.

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures.

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ 1.0sg = 8.345ppg

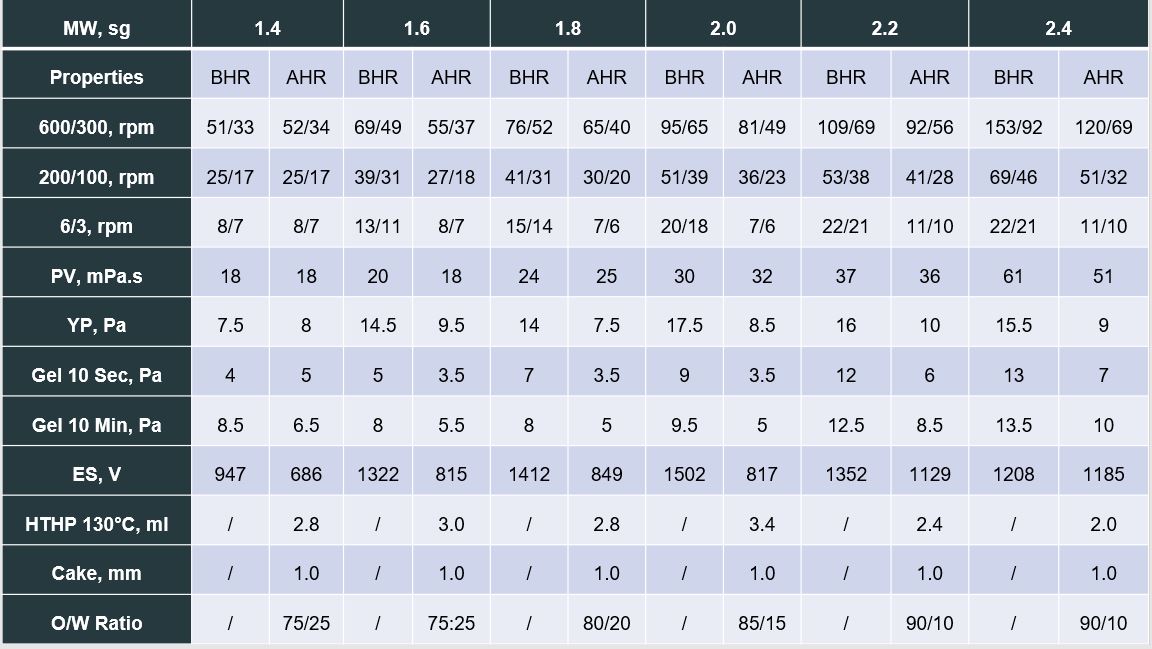

¬ Hot rolled at 265°F (130°C), 16hrs

¬ Rheology properties are tested at 150°F (65°C)