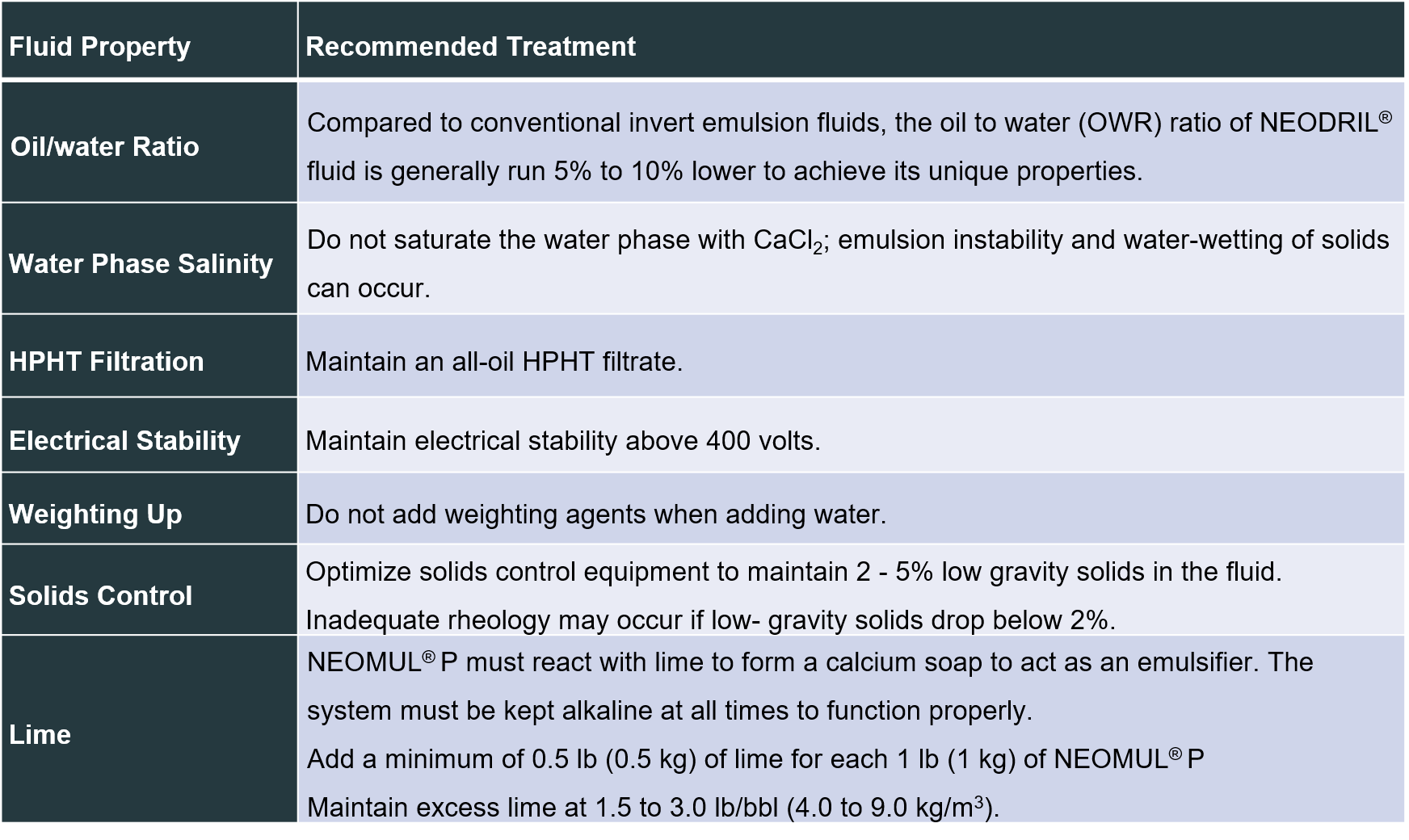

NEODRIL® High-Performance oil-based mud system is state-of-the-art technology among competing invert emulsion systems as a true Clay-free system without any organic clay, organophilic lignite, asphalt or gilsonite additives and so on traditional black powder products.

Minimizing solids content and a unique gel structure allows the NEODRIL® system to boost the best drilling performance through lowest equivalent circulation density (ECD) achieved, best penetration rate, non-damage to reservoir and sag-free in any diesel or mineral oil-based applications. This makes NEODRIL® the ideal choice to drill ERD wells with lateral section over 3500m length in shale gas blocks of Southwest China.

- Use polymer and emulsion technology to rapidly create a "rapid-set/easy-break" gel strength.

- Stable mud properties over a wide temperature and density range (400+°F and 18.0+ ppg).

- Fragile gel strengths that can significantly reduce downhole losses - which can lower operating costs and lessen environmental impact when compared to conventional invert emulsion fluids.

- Unique rheological properties that can provide low ECDs with greater suspension properties, eliminating the need for fine ground weighting agents while providing excellent hole cleaning.

- Significantly lower solids with maximized flow rate achieved for more horsepower to the motor and bit resulting in increased ROP.

- Fewer products than required for conventional synthetics, improving logistics and rig space usage.

- No sag in hole or circulating to stabilize mud weight after long static periods.

- Extremely thin filter cake and low fluid invasion to promote optimal logging conditions, superior return permeability and low lift-off pressures.

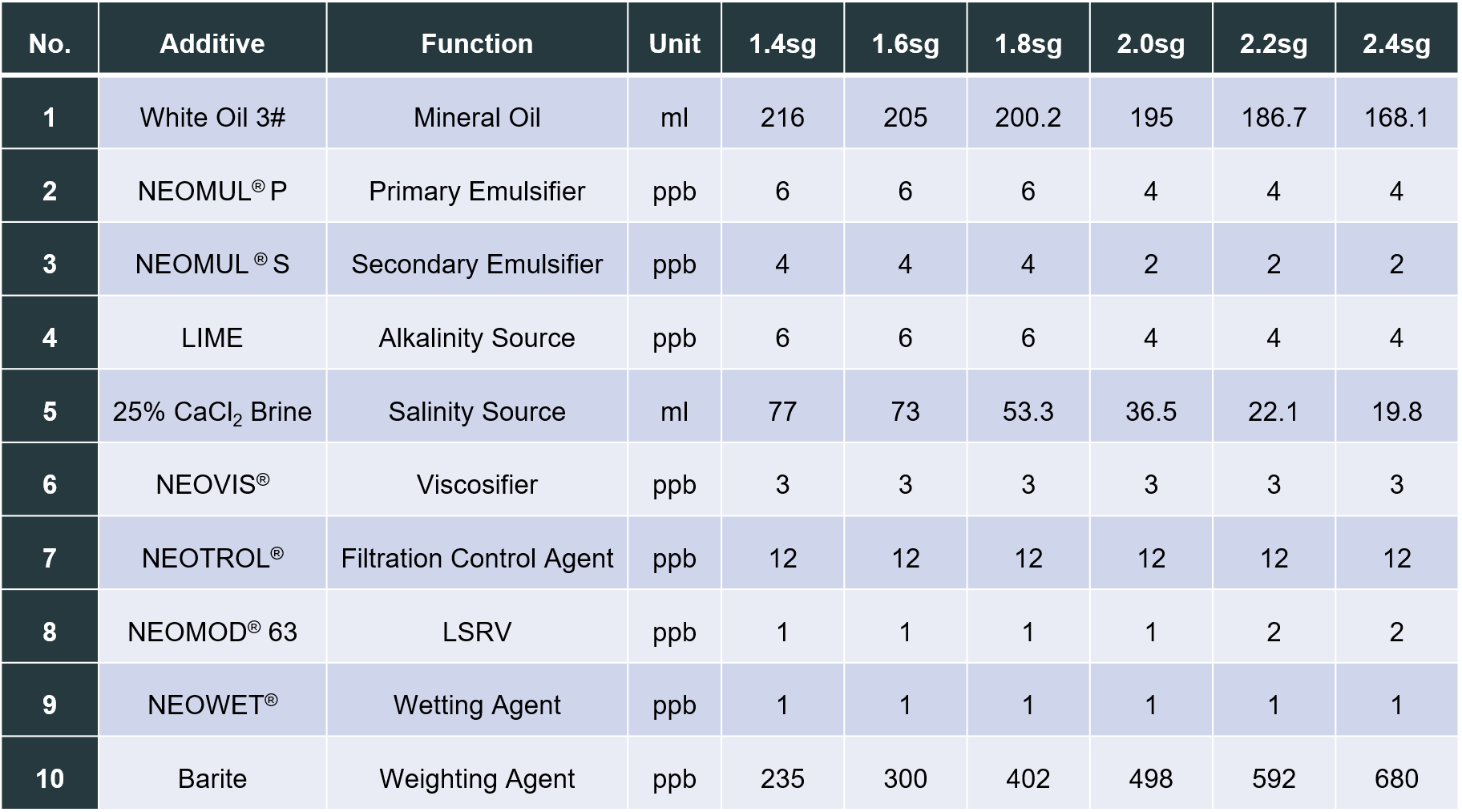

¬ The amount of each above product added into the formulation is g or ml to mix 350 ml (1bbl) volume sample.

¬ Either diesel oil OR mineral oil is used as the base fluid for conventional oil-based mud systems.

¬ Use NEOMOD® 63 to enhance low shear-rate viscosities of NEODRIL® system.

¬ These formulas are specially designed for long horizontal section or high angle hole drilling.

¬ Pilot testing should be performed to determine the exact amount of each product used in a particular formulation under elevated temperatures.

¬ 1ppb = 2.857kg/m3, 1ppb = 1g/350ml

¬ 1.0sg = 8.345ppg

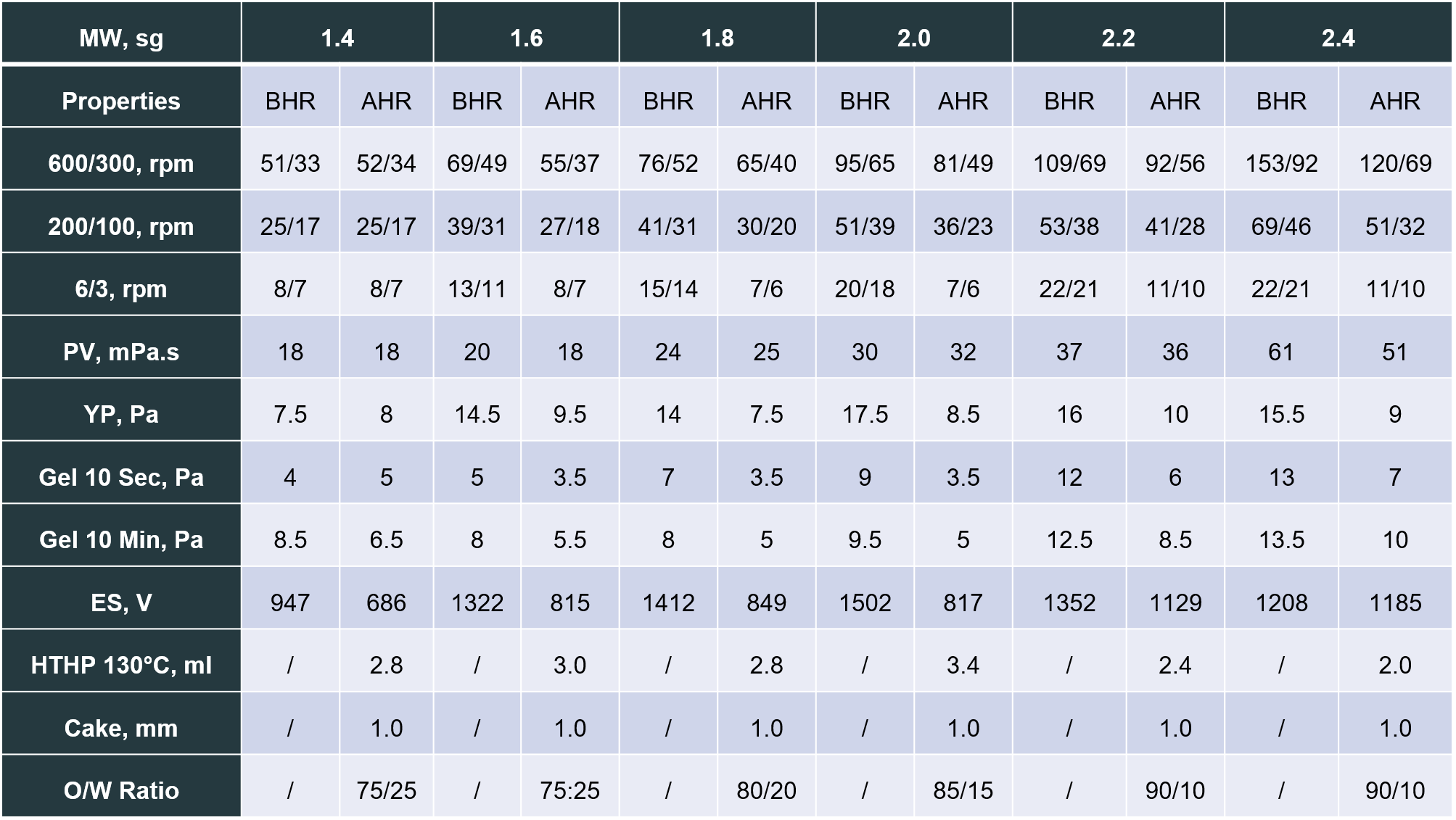

¬ Hot rolled at 265°F (130°C), 16hrs.

¬ Rheology properties are tested at 150°F (65°C).